Causes of Excavator Track Chain Derailment and How to Prevent It

excavators play a crucial role in construction and heavy machinery operations. However, track chain derailment is a common issue that can affect operational efficiency and lead to equipment damage. Understanding the causes of derailment and preventive measures is essential for maintaining the smooth operation of excavators.

Causes of Derailment

Track Wear Over time, the track chains experience wear and tear, which can lead to a decline in structural integrity. When the wear becomes excessive, the track chain is more prone to derailment during operation.

Insufficient Tension If the track chain tension is inadequate, the chain may become loose during operation, increasing the likelihood of derailment. Maintaining proper tension is critical for stable chain performance.

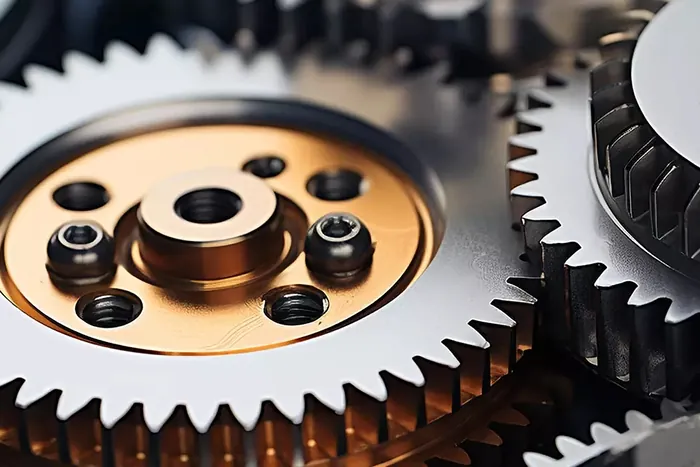

Damage to sprockets or Rollers sprockets and rollers guide and support the track chain during operation. If these components are damaged or worn, the chain's trajectory will be affected, leading to a higher risk of derailment.

Improper Operation Incorrect operational practices, such as sharp turns, rapid acceleration, or abrupt braking, can place additional stress on the track chain, increasing the chances of derailment.

Environmental Factors Uneven construction sites, obstacles, or muddy ground can destabilize the track chain during operation, resulting in derailment.

Methods to Prevent Track Chain Derailment

Regular Inspection and Maintenance Conduct regular inspections of the track chains, sprockets, and rollers to ensure they are in good working condition. Promptly replace worn components to extend the lifespan of the equipment.

Adjust Track Tension Ensure that the track chain maintains proper tension. Operators should regularly check the tension and make adjustments as necessary to prevent looseness.

Follow Proper Operating Procedures Provide training for operators to ensure they understand correct operational methods. Avoid sharp turns and rapid acceleration, and strive for smooth operation to minimize impact on the track chain.

Improve the Work Environment Before starting work, clear the construction site and maintain a level surface to avoid excessive obstacles. Additionally, refrain from operating on excessively muddy or soft ground.

Use Appropriate Lubricants Regularly apply lubricants to the track chain and related components to reduce friction and wear, thereby extending the equipment's lifespan.

Conclusion

Track chain derailment in excavators is a significant safety concern that should not be overlooked. By understanding the causes and implementing effective preventive measures, the risk of derailment can be substantially reduced, enhancing operational efficiency and safety. Regular maintenance and operator training are key to ensuring the smooth operation of excavators.

Why Choose SAIVS™ as Your Supplier?

Committed to innovation and customer needs, SAIVS specializes in high-quality machinery components for diverse industries like construction, mining, and agriculture. They offer a wide range of parts, including undercarriage components for popular brands, ensuring optimal performance and durability. values customer satisfaction, providing competitive prices, fast shipping, and exceptional service to keep your operations running smoothly.