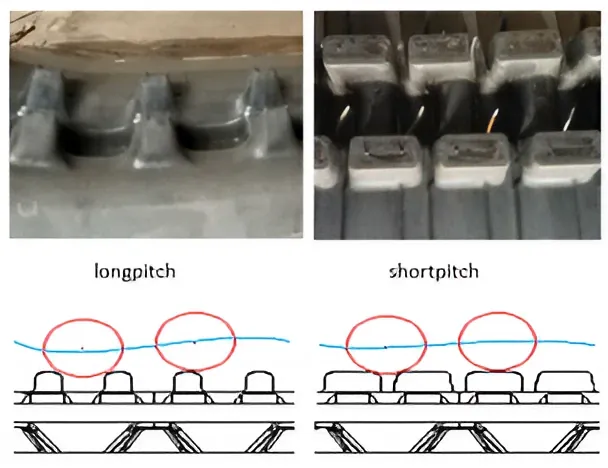

Exploring the Distinctions Between Long Pitch and Short Pitch Rubber Tracks

rubber tracks are integral components in various tracked vehicles, offering traction, stability, and maneuverability across diverse terrains. Understanding the differences between long pitch and short pitch rubber tracks is crucial for selecting the most suitable option based on specific application requirements. In this article, we delve into the key differentiating factors between these two types of rubber tracks.

Long Pitch Rubber Tracks

Long pitch rubber tracks are characterized by a larger pitch distance between the drive lugs or cleats. The pitch distance refers to the center-to-center spacing of the drive lugs along the track. Long pitch tracks typically have fewer drive lugs per unit length compared to short pitch tracks. This design feature offers several advantages:

1. Reduced Vibration and Noise: Long pitch tracks exhibit smoother operation due to the larger gaps between drive lugs, resulting in reduced vibration and noise levels during operation.

2. Enhanced Traction: The larger surface area of the drive lugs provides increased traction, particularly in soft or muddy terrain, allowing for improved vehicle stability and maneuverability.

3. Extended Lifespan: Long pitch tracks experience less wear and tear on the drive lugs and track components due to reduced friction, resulting in a longer service life compared to short pitch tracks.

Short Pitch Rubber Tracks

Short pitch rubber tracks feature a smaller pitch distance between drive lugs, resulting in a higher number of drive lugs per unit length along the track. This design configuration offers distinct advantages:

1. Improved Durability: Short pitch tracks distribute the vehicle's weight more evenly across a greater number of drive lugs, reducing individual lug wear and enhancing overall track durability, especially in high-load applications.

2. Enhanced Stability: The higher number of drive lugs provides increased contact points with the terrain, enhancing stability and reducing the risk of slippage, particularly on uneven surfaces or steep inclines.

3. Greater Precision: Short pitch tracks offer finer control and maneuverability, making them ideal for applications requiring precise movements or operations in confined spaces.

Conclusion

In summary, the choice between long pitch and short pitch rubber tracks depends on various factors such as terrain conditions, load capacity, maneuverability requirements, and desired lifespan. Long pitch tracks excel in providing smooth operation, enhanced traction, and prolonged durability, while short pitch tracks offer improved stability, precision, and load-bearing capacity. By understanding the distinctions between these two types of rubber tracks, users can make informed decisions to optimize the performance and longevity of tracked vehicles in diverse operating environments.

Why Choose SAIVS™ as Your Supplier?

Committed to innovation and customer needs, SAIVS specializes in high-quality machinery components for diverse industries like construction, mining, and agriculture. They offer a wide range of parts, including undercarriage components for popular brands, ensuring optimal performance and durability. values customer satisfaction, providing competitive prices, fast shipping, and exceptional service to keep your operations running smoothly.