EC200 Sprocket for Excavator Part

-

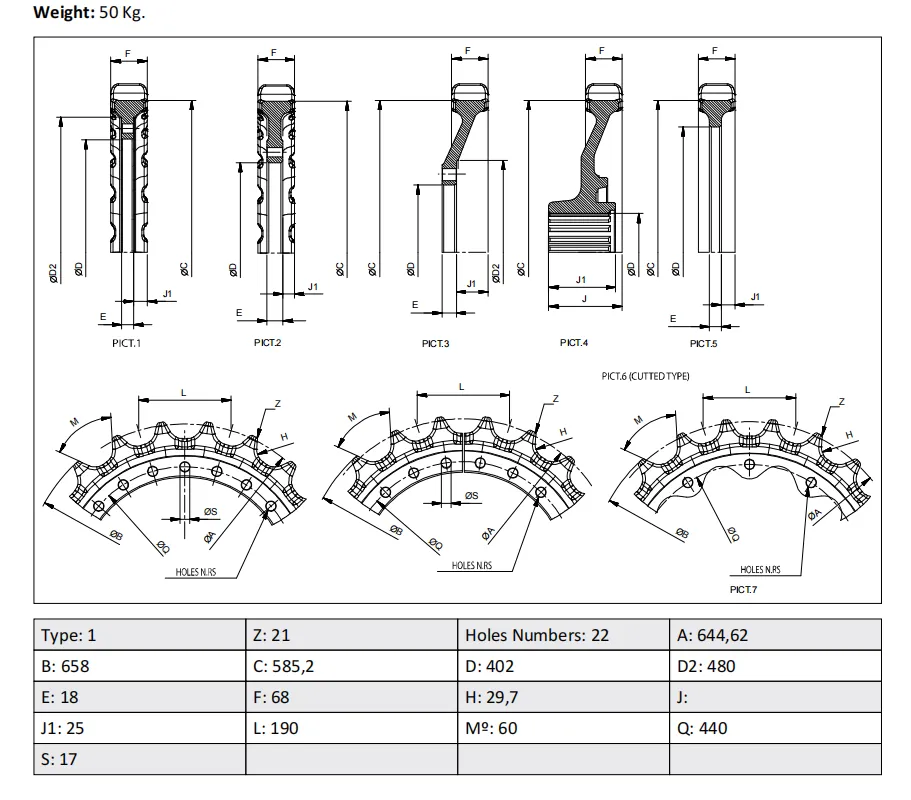

Weight:50kg

Material:35SiMn/40Mn2

Finish:Smooth

Colors:Black or yellow

Technique:Forging casting

Surface Hardness:HRC50-56,deepth:4mm-10mm

Warranty time:2000 hour

Certification:ISO9001-9002

FOB Price:FOB Ningbo USD 10-100/Piece

MOQ:10 piece

Delivery Time:Within 30 days after contract established

Description

COMPATIBLE WITH THE FOLLOWING VEHICLES:

JCB817

VOLVO

EC200, EC200

We offer premium quality Sprocket & Segment for renowned brands like CAT, CATERPILLAR, DAEWOO, DOOSAN,

HITACHI,JCB,JOHN DEERE,KATO,KOMATSU,KUBOTA,LIEBHERR,MITSUBISHI,CASE,SHANTUI,TEREX,VOLVO,YANMAR,and many more.

Rest assured, our products boast an extended lifespan, ensuring reliable performance even under the harshest conditions.

Image Gallery

Models

| PC120-6 | PC130 | PC130-7 | PC200 | PC200-1 | PC200-3 | PC200-5 | PC200-6 | PC200-7 |

|---|---|---|---|---|---|---|---|---|

| PC200-8 | PC210-6 | PC220-1 | PC220-3 | PC220-6 | PC220-7 | PC220-8 | PC270-7 | PC202B |

| PC20-7 | PC30 | PC30-3 | PC30-5 | PC30-6 | PC40-7 | PC45 | PC45-2 | PC55 |

| PC220LC-6 | PC220LC-8 | PC240 | PC300 | PC300-3 | PC300-5 | PC300-6 | PC300-7 | PC300-7K |

| PC300LC-7 | PC350-6/7 | PC400 | PC400-3 | PC400-5 | PC400-6 | PC400LC-7 | PC450-6 | PC450-7 |

| PC600 | PC650 | PC750 | PC800 | PC1100 | PC1250 | PC2000 | ||

| EX100 | EX110 | EX120 | EX120-1 | EX120-2 | EX120-3 | EX120-5 | EX130-1 | EX200-1 |

| EX200-2 | EX200-3 | EX200-5 | EX220-3 | EX220-5 | EX270 | EX300 | EX300-1 | EX300-2 |

| EX300-3 | EX300-5 | EX300A | EX330 | EX370 | EX400-1 | EX400-2 | EX400-3 | EX400-5 |

| EX40-1 | EX40-2 | EX55 | EX60 | EX60-2 | EX60-3 | EX60-5 | EX70 | EX75 |

| EX450 | ZAX30 | ZAX55 | ZAX200 | ZAX200-2 | ZAX330 | ZAX450-1 | ZAX450-3 | ZAX450-5 |

| ZX110 | ZX120 | ZX200 | ZX200 | ZX200-1 | ZX200-3 | ZX200-59 | ZX200LC-3 | ZX210 |

| ZX210-3 | ZX210-3 | ZX210-5 | ZX225 | ZX240 | ZX250 | ZX270 | ZX30 | ZX330 |

| ZX330 | ZX350 | ZX330C | ZX450 | ZX50 | ||||

| E200B | E200-5 | E320D | E215 | E320DL | E324D | E324DL | E329DL | E300L |

| E3205 | E320 | E320DL | E240 | E120-1 | E311 | E312B | E320BL | E345 |

| E324 | E140 | E300B | E330C | E120 | E70 | E322C | E322B | E325 |

| E325L | E330 | E450 | CAT225 | CAT312B | CAT315 | CAT320 | CAT320C | CAT320BL |

| CAT330 | CAT322 | CAT245 | CAT325 | CAT320L | CAT973 | |||

| SH120 | SH120-3 | SH200 | SH210-5 | SH200 | SH220-3 | SH220-5/7 | SH290-3 | SH350-5/7 |

| SH220 | SH280 | SH290-7 | SH260 | SH300 | SH300-3 | SH300-5 | SH350 | SH60 |

| SH430 | ||||||||

| SK120-6 | SK120-5 | SK210-8 | SK210LC-8 | SK220 | SK220-1 | SK220-3 | SK220-5/6 | SK200 |

| SK200 | SK200 | SK200-3 | SK200-6 | SK200-8 | SK200-5/6 | SK60 | SK290 | SK100 |

| SK230 | SK250 | SK250-8 | SK260LC-8 | SK300 | SK300-2 | SK300-4 | SK310 | SK320 |

| SK330-8 | SK330 | SK350LC-8 | SK235SR | SK450 | SK480 | SK30-6 | ||

| DH200 | DH220-3 | DH220 | DH2205 | DH280-2 | DH280-3 | DH55 | DH258 | DH130 |

| DH370 | DH80 | DH500 | DH450 | DH225 | ||||

| R60-5 | R60-7 | R60-7 | R80-7 | R200 | R200-3 | R210 | R210 | R210-9 |

| R210LC | R210LC-7 | R225 | R225-3 | R225-7 | R250 | R250-7 | R290 | R290LC |

| R290LC-7 | R320 | R360 | R954 | |||||

| HD512 | HD1430 | HD512III | HD820III | HD820R | HD1430III | HD700VII | HD1250VII | HD250SE |

| HD400SE | HD550SE | HD1880 | ||||||

| DX225 | DX225LCA | DX258 | DX300 | DX300LCA | DX420 | DX430 | ||

| EC160C | EC160D | EC180B | EC180C | EC180D | EC210 | EC210 | EC210B | EC240B |

| EC290 | EC290B | EC240 | EC55 | EC360 | EC360B | EC380D | EC460 | EC460B |

| EC460C | EC700 | EC140 | EC140B | EC160B |

Video

FAQs

Q: Is the excavator sprocket compatible with different excavator models?

A: Excavator sprockets are specifically designed to fit particular excavator models or series. While some sprockets may be compatible with multiple models within the same brand or series, it's essential to verify compatibility with the specific make, model, and size of the excavator to ensure proper fitment and performance.

Q: How can operators maintain the excavator sprocket for optimal performance?

A: Regular inspection and maintenance are essential to keep the excavator sprocket in optimal condition. Operators should routinely check for signs of wear,

damage, or misalignment and address any issues promptly. Proper lubrication of the sprocket's components is also critical to minimize friction and prevent

premature wear. Following the manufacturer's recommendations for maintenance intervals and procedures is advisable to ensure reliable performance and

extend the sprocket's lifespan.

Q: What sets a high-quality excavator sprocket apart from others on the market?

A: A high-quality excavator sprocket stands out due to its durability, precision engineering, and reliability. It is designed to withstand the demanding conditions

of excavation work, offering superior performance and longevity. Premium materials, advanced manufacturing techniques, and stringent quality control ensure

consistent quality and optimal functionality, making it a preferred choice for excavator operators and contractors seeking reliability and efficiency.

Literature

Comment

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

When seeking manufacturers and suppliers for EC200 Sprocket for Excavator Part, choosing SAIVS is your wise decision.

We pride ourselves on high quality, diverse options, competitive pricing, and swift delivery.

Engage with our experts now to explore further insights into our EC200 Sprocket for Excavator Part product solutions.