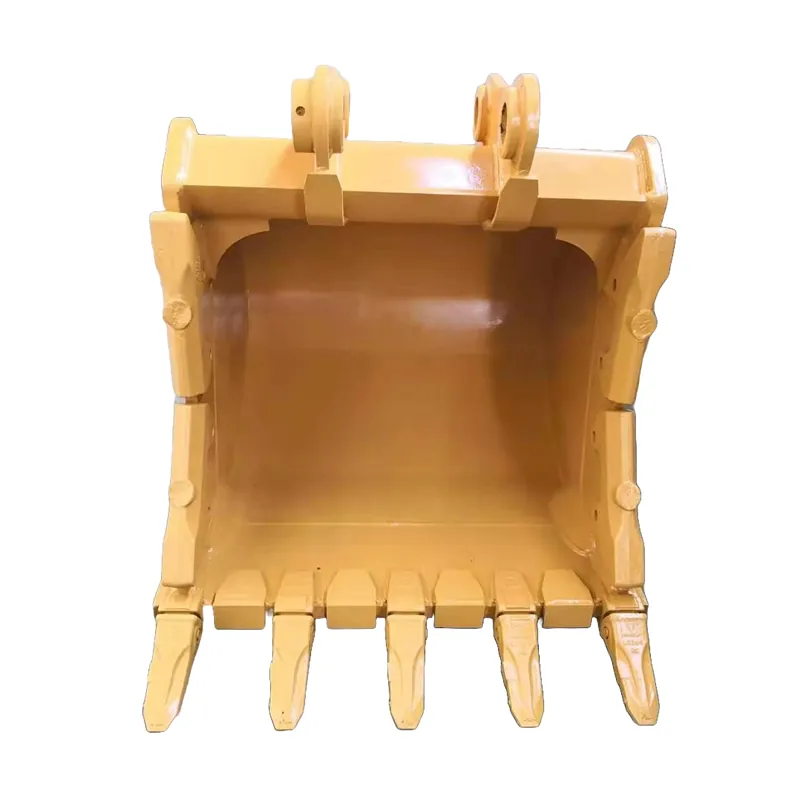

EC210B Rock Bucket for Excavator

-

Material:Q345B

Finish:Smooth

Colors:Black or yellow(Customized)

Technique:Forging casting

Trademark:OEM

Warranty time:2000 hour

Certification:ISO9001-9002

MOQ:1 piece

Delivery Time:Within 40 days after contract established

Warranty: One Year

Excavator Brands: The products we offer are fitted for all of the world famous excavator brands

Description

excavator buckets are important components in the construction industry and are used in various operations under relatively harsh conditions such as light

mining, hard excavation, and loading of small rocks. Our line of excavator buckets is designed to meet all your needs, from excavation buckets to V-buckets,

Rock Buckets, clean-up buckets, skeleton buckets and trenching buckets. Our excavator buckets feature a robust design and high-quality materials to ensure efficient and seamless operation on your job site.

Bucket Design: Heavy duty flat floor design with outside bottom wear strips, upper and lower side kick plates.

Bucket Shape: Straight or spade lip, vertical shrouds, optional weld-on lip shrouds or J-bolt lip shrouds.

Enhanced bucket shap allows material to flow more easily.

Tapered bucket sidewalls allow for easy dumping of sticky material.

Superior bucket fill: Optimum wrapper angle and no sharp corners promote superior bucket fill and reduce material packing.

Application: Applicable to slope-surface trimming,waterways dredging,water ditching,etc.

Designed for a wide variety of applications and materials.

Kindly recommended for dirt, loam, gravel, loose clay, non-abrasive soils with limited rock.

We offer premium quality Excavator Bucket for renowned brands like CAT, CATERPILLAR, DAEWOO, DOOSAN,

HITACHI,JCB,JOHN DEERE,KATO,KOMATSU,KUBOTA,LIEBHERR,MITSUBISHI,CASE,SHANTUI,TEREX,VOLVO,YANMAR,and many more.

Rest assured, our products boast an extended lifespan, ensuring reliable performance even under the harshest conditions.

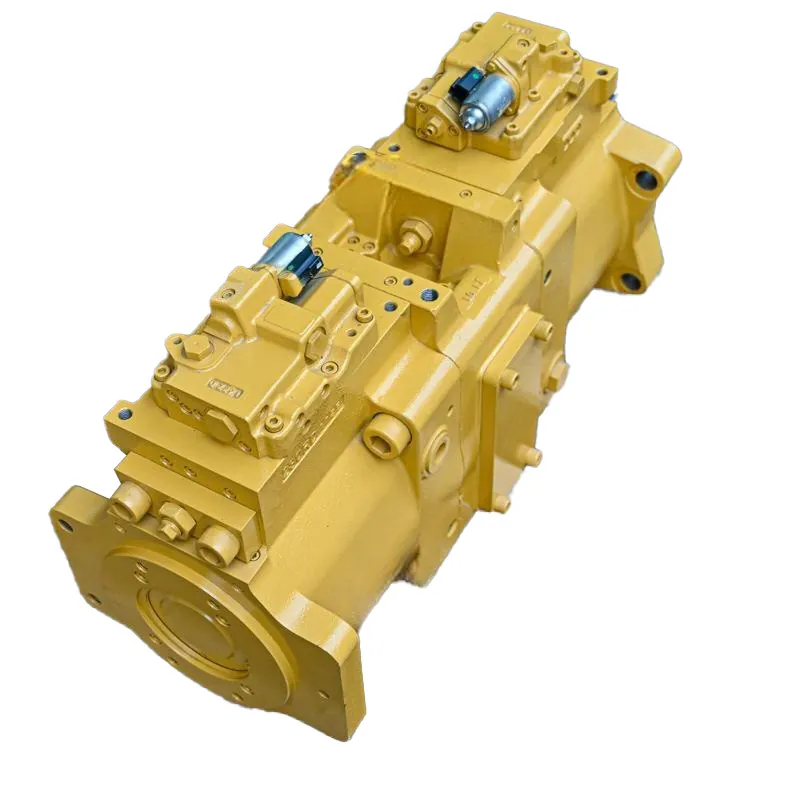

Image Gallery

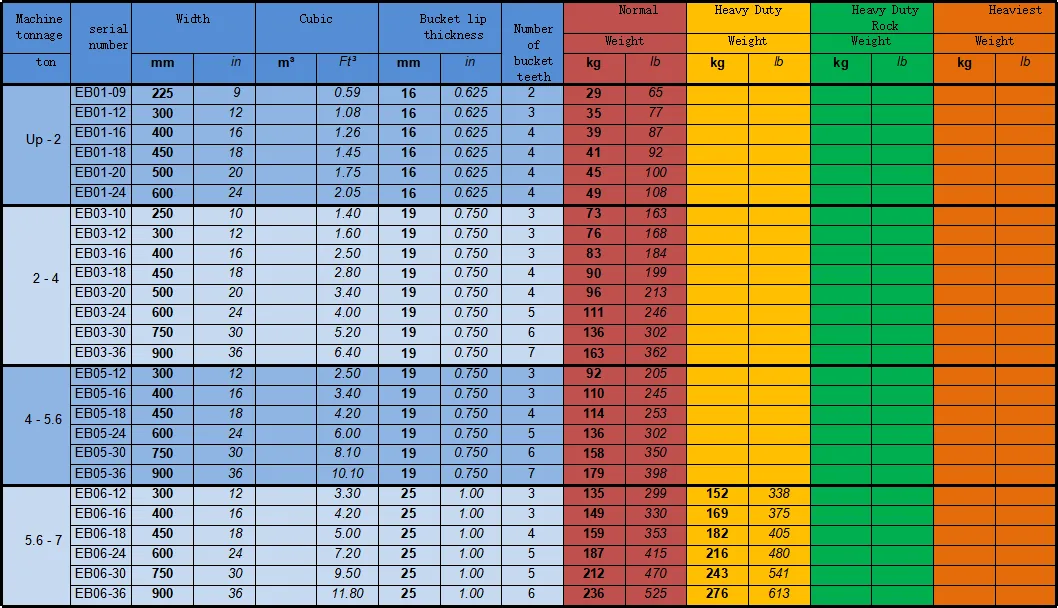

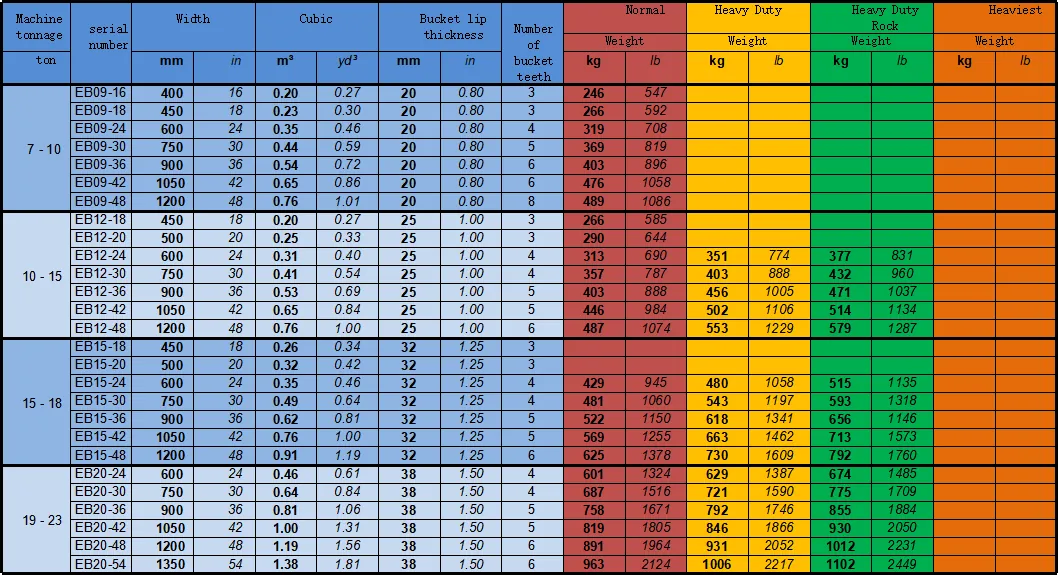

Dimensions

FAQs

Q:What buckets can you made?

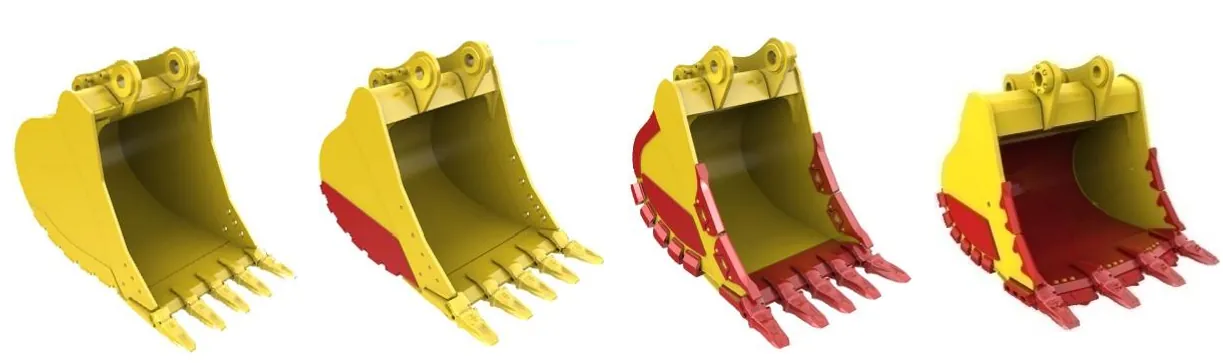

Standard Bucket / Heavy Duty Bucket/Rock Bucket/Mining Bucket

Face Shovel Bucket

Grab Bucket

Tilt Bucket

Cleaning Bucket

Sieve Bucket

Clamshell Bucket

Rotary Screening Bucket

Wedge Type Bucket

Other series you need

A:If you don't see the specific model or product you need, please email us or use our website contact form. We'll get back to you right away!

Q: What types of materials can be screened with a screening bucket?

A: A screening bucket can efficiently screen a variety of materials, including topsoil, sand, gravel, demolition waste, compost, and biomass.

It is versatile enough to handle different types of materials encountered in construction, landscaping, and recycling applications.

Q: What are the advantages of using a screening bucket?

A: Some advantages of using a screening bucket include:

On-site material screening, reducing the need for separate screening equipment.

Time and cost savings by eliminating the transportation of materials to off-site screening facilities.

Increased efficiency and productivity in excavation and construction projects.

Ability to reuse and recycle screened materials, promoting sustainability.

Literature

Comment

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

When seeking manufacturers and suppliers for EC210B Rock Bucket for Excavator, choosing SAIVS is your wise decision.

We pride ourselves on high quality, diverse options, competitive pricing, and swift delivery.

Engage with our experts now to explore further insights into our EC210B Rock Bucket for Excavator product solutions.