Hyundai290-7 Track Pins for Excavator

-

Product Information:excavator and bulldozer pins

Material:40cr/45#

Technique:Forging & casting

Heat treatment:50-53 HRC

Warranty time:2000 hour (Normal life 4000hours )

Certification:ISO9001-9002

MOQ:10 pieces

Delivery Time:Within 30 days after contract established

Size:Customized

Description

The bucket pins are essential wear parts for excavator bucket attachments.

There are various materials used for bucket bushings, with the main options being 45# carbon steel, 40Cr, and 20CrMnTi.

In addition to selecting the appropriate raw materials, heat treatment plays a crucial role in ensuring the quality and durability of these components.

We offer premium quality Bucket Pin & Bucket Bushing for renowned brands like CAT, CATERPILLAR, DAEWOO, DOOSAN,

HITACHI,JCB,JOHN DEERE,KATO,KOMATSU,KUBOTA,LIEBHERR,MITSUBISHI,CASE,SHANTUI,TEREX,VOLVO,YANMAR,and many more.

Rest assured, our products boast an extended lifespan, ensuring reliable performance even under the harshest conditions.

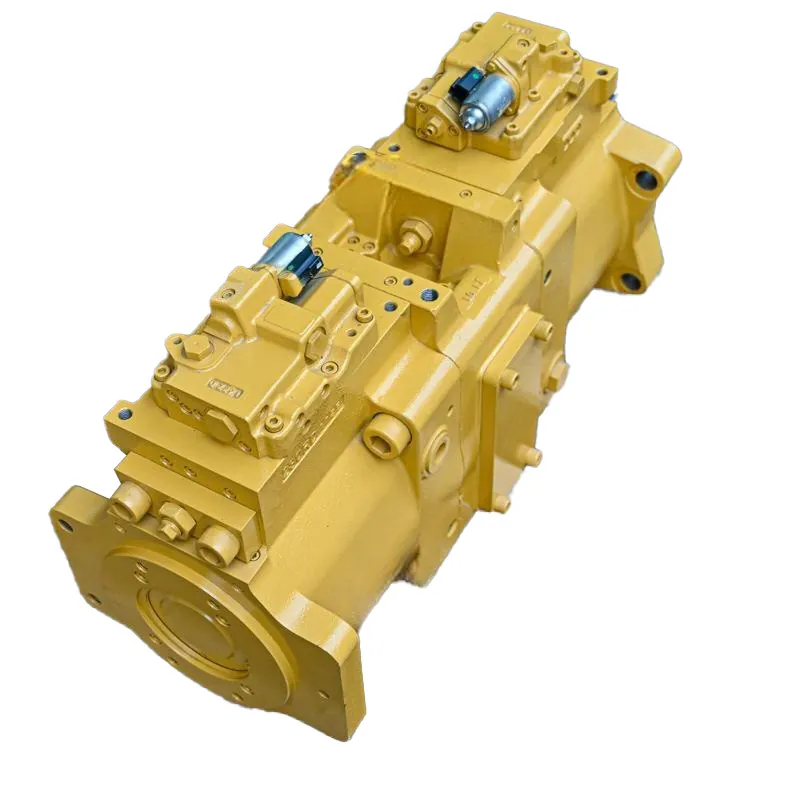

Image Gallery

Models

| PART NO. | BUCKET PIN | Model | Material |

| 90×580 | BUCKET PIN | CAT 325DL | 40Cr |

| 80×543 | BUCKET PIN | CAT320DL | 40Cr |

| 90×580 | BUCKET PIN | Doosan DX300-LCA | 40Cr |

| 70x450 | BUCKET PIN | E320 | 40Cr |

| 80x450 | BUCKET PIN | E320 | 40Cr |

| 80x545 | BUCKET PIN | E320 | 40Cr |

| 80x430 | BUCKET PIN | EX200 | 40Cr |

| 80x500 | BUCKET PIN | EX200 | 40Cr |

| 90×630 | BUCKET PIN | Hyundai 290-7 | 40Cr |

| 90×620 | BUCKET PIN | Hyundai 290-7 | 40Cr |

| 140x890 | BUCKET PIN | PC1250 | 40Cr |

| 140x980 | BUCKET PIN | PC1250 | 40Cr |

| 80x560 | BUCKET PIN | PC200 | 40Cr |

| 80x530 | BUCKET PIN | PC200 | 40Cr |

| 70x480 | BUCKET PIN | PC200 | 40Cr |

| 70x430 | BUCKET PIN | PC200 | 40Cr |

| 80x540 | BUCKET PIN | PC200 | 40Cr |

| 115x730 | BUCKET PIN | PC750/PC800 | 40Cr |

| 130x830 | BUCKET PIN | PC750/PC800 | 40Cr |

| 70x480 | BUCKET PIN | SK200 | 40Cr |

| 80x480 | BUCKET PIN | SK200 | 40Cr |

| 80x540 | BUCKET PIN | SK200 | 40Cr |

| 130x870 | BUCKET PIN | ZX870 | 40Cr |

| 100x620 | BUCKET PIN | PC450 | 40Cr |

| 100x680 | BUCKET PIN | PC450 | 40Cr |

| 90x620 | BUCKET PIN | PC350 | 40Cr |

Video

FAQs

1. Are there aftermarket options available for Track Pins and Bushings?

Yes, there are aftermarket options available for track pins and bushings, including OEM (Original Equipment Manufacturer) replacements and aftermarket

alternatives. These options may vary in terms of quality, price, and compatibility with specific machinery models.

2. What factors should be considered when selecting Track Pins and Bushings?

When selecting track pins and bushings, factors such as material quality, compatibility with the machinery, expected workload, and operating conditions should

be taken into account. Choosing components that meet the required specifications and quality standards is essential for optimal performance and durability.

3. Can Track Pins and Bushings be replaced individually, or are they typically replaced as part of a larger assembly?

Track pins and bushings can be replaced individually if only certain components are worn or damaged. However, in cases where significant wear or damage is

observed across the entire assembly, it may be more practical to replace the entire track assembly for better overall performance and longevity.

Literature

Comment

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

When seeking manufacturers and suppliers for Hyundai290-7 Track Pins for Excavator, choosing SAIVS is your wise decision.

We pride ourselves on high quality, diverse options, competitive pricing, and swift delivery.

Engage with our experts now to explore further insights into our Hyundai290-7 Track Pins for Excavator product solutions.