PC200 Bucket linkage for Excavator

-

Material:42CrMo

Finish:Smooth

Colors:Black or yellow,Customized

Technique:Forging casting

Warranty time:2000 hour

Certification:ISO9001-9002

MOQ:3 piece

Delivery Time:Within 20 days after contract established

Quenching Depthth:5-8mm

Description

bucket linkage for all bucket Casting and welding type Replacement bucket link for

Caterpillar, Komatsu, Hitachi, Kobelco, Mitsubishi, Sumitomo,Daewoo, Hyundai

We offer premium quality Bucket Linkage for renowned brands like CAT, CATERPILLAR, DAEWOO, DOOSAN,

HITACHI,JCB,JOHN DEERE,KATO,KOMATSU,KUBOTA,LIEBHERR,MITSUBISHI,CASE,SHANTUI,TEREX,VOLVO,YANMAR,and many more.

Rest assured, our products boast an extended lifespan, ensuring reliable performance even under the harshest conditions.

Image Gallery

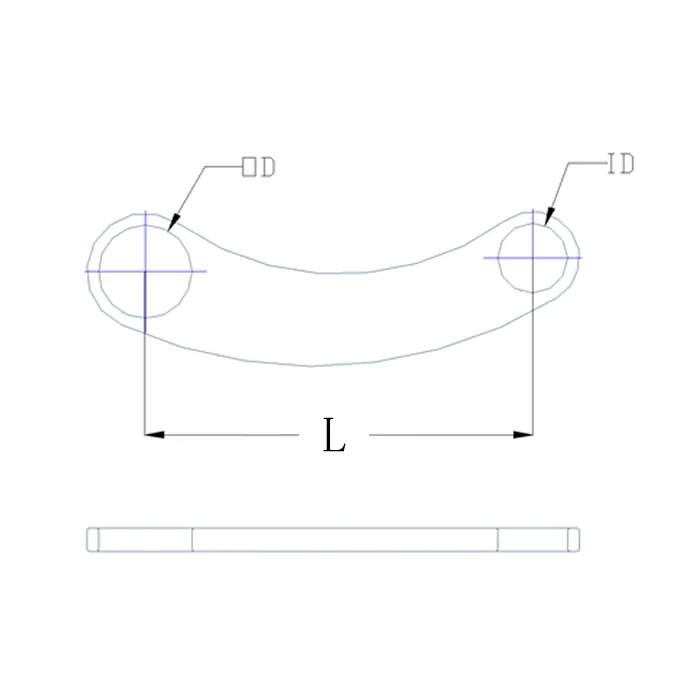

Dimensions

| Model | ID/mm | OD/mm | L/mm | Weight/K |

| PC60 | 50 | 60 | 400 | 15 |

| PC100 | 50 | 60 | 490 | 19 |

| PC120 | 60 | 65 | 490 | 20 |

| PC200-5 | 70 | 70 | 620 | 32 |

| PC200-6 | 70 | 80 | 645 | 31 |

| PC220-6 | 80 | 80 | 595 | 32 |

| PC360 | 90 | 90 | 730 | 68 |

| PC400/4.0 | 100 | 100 | 730 | 65 |

| E306 | 45 | 45 | 360 | 11.5 |

| E307 | 50 | 55 | 410 | 12 |

| E708 | 50 | 60 | 420 | 11 |

| E312/E312D | 65 | 70 | 520 | 23 |

| E312 | 65 | 70 | 520 | 24 |

| E320D | 70 | 80 | 585 | 31 |

| E320D | 70 | 80 | 640 | 33 |

| E325D | 90 | 90 | 650 | 49 |

| E329D | 70 | 90 | 680 | 49 |

| E324D | 70 | 80 | 695 | 35.5 |

| E336D | 56 | |||

| E330C | 70 | 100 | 685 | 64 |

| EX55 | 45 | 50 | 340 | 12.5 |

| ZAX55 | 45 | 50 | 340 | 12.5 |

| EX60 | 45 | 55 | 410 | 15 |

| ZAX60 | 45 | 50 | 320 | 11.5 |

| EX70 | 50 | 55 | 420 | 14 |

| EX100 | 65 | 65 | 450 | 25 |

| EX120 | 65 | 65 | 500 | 21 |

| EX200-5 | 71 | 80 | 600 | 32 |

| EX230 | 80 | 90 | 620 | 40.5 |

| EX300 | 90 | 100 | 730 | 60 |

| ZAX360 | 90 | 100 | 690 | 66 |

| SH120 | 65 | 65 | 525 | 19 |

| SH200 | 75 | 85 | 600 | 31.5 |

| SH280 | 70 | 80 | 585 | 33 |

| SH240 | 41 | |||

| DH55 | 45 | 50 | 350 | 15 |

| DH55 | 45 | 50 | 350 | 18 |

| DH80 | 45 | 55 | 400 | 14 |

| DH150 | 65 | 65 | 510 | 20 |

| DH220 | 70 | 80 | 600 | 33 |

| DH300 | 80 | 90 | 665 | 49 |

| DH380 | 90 | 100 | 740 | 70 |

| R60 | 45 | 45 | 320 | 10 |

| R80 | 55 | 55 | 400 | 13 |

| R200 | 70 | 70 | 635 | 32 |

| R225-7 | 70 | 80 | 610 | 32 |

| R275 | 80 | 80 | 670 | 45.5 |

| R305 | 80 | 80 | 680 | 44.5 |

| SK60 | 50 | 50 | 420 | 14.5 |

| SK75 | 50 | 50 | 420 | 13 |

| SK100 | 60 | 60 | 515 | 20.5 |

| SK120 | 60 | 60 | 515 | 23.5 |

| SK140 | 60 | 65 | 410 | 20 |

| SK200 | 70 | 80 | 635 | 32 |

| SK230 | 70 | 80 | 695 | 35.5 |

| SK350 | 80 | 90 | 700 | 52 |

| SK450/SK460 | 100 | 100 | 770 | 74 |

| EC55 | 45 | 45 | 370 | 13 |

| EC80 | 60 | 60 | 420 | 17.5 |

| EC140 | 71 | 80 | 600 | 23 |

| EC210 | 70 | 80 | 600 | 33 |

| EC290 | 90 | 90 | 650 | 49 |

| EC360 | 100 | 100 | 720 | 57 |

| EC460 | 110 | 100 | 750 | 71 |

| SY75 | 50 | 50 | 400 | 14.5 |

| SY230 | 80 | 80 | 590 | 30 |

| SY235 | 90 | 90 | 645 | 49 |

| SY60 | 50 | 50 | 360 | 15 |

| SY135 | 65 | 65 | 515 | 24 |

| SY335 | 53 | |||

| HD700 | 70 | 80 | 640 | 38 |

| HD820 | 70 | 80 | 640 | 34 |

| HD820 | 70 | 80 | 640 | 43 |

| HD1023 | 70 | 85 | 640 | 34 |

| YC85 | 50 | 55 | 390 | 13 |

| SWE50 | 55 | 55 | 370 | 20 |

| SWE70 | 55 | 55 | 37 | 17 |

| ZY80 | 60 | 60 | 350 | 12.5 |

| CASE70 | 50 | 55 | 380 | 18 |

| KY70 | 50 | 50 | 370 | 15 |

| JCB230 | 80 | 90 | 570 | 43 |

| XG60 | 45 | 55 | 400 | 13 |

| XG815 | 65 | 65 | 490 | 23 |

FAQs

1. What types of movements can be achieved with a bucket linkage?

A bucket linkage allows for various movements, including raising, lowering, tilting, and rotating the bucket. These movements are essential for performing tasks

such as digging, loading, dumping, and leveling materials on construction sites.

2. How can operators detect problems with bucket linkages?

Operators can detect problems with bucket linkages by performing visual inspections, listening for unusual noises during operation, and observing any irregularities in the bucket's movement or response to hydraulic controls. Any signs of wear, damage, or malfunction should be reported and addressed promptly.

3. What are the safety considerations when working with bucket linkages?

Safety considerations when working with bucket linkages include following proper operating procedures, wearing appropriate personal protective equipment, and maintaining a safe distance from moving parts during operation. Operators should also be trained in equipment operation and maintenance to prevent

accidents and injuries.

Literature

Comment

Tags

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

When seeking manufacturers and suppliers for PC200 Bucket linkage for Excavator, choosing SAIVS is your wise decision.

We pride ourselves on high quality, diverse options, competitive pricing, and swift delivery.

Engage with our experts now to explore further insights into our PC200 Bucket linkage for Excavator product solutions.