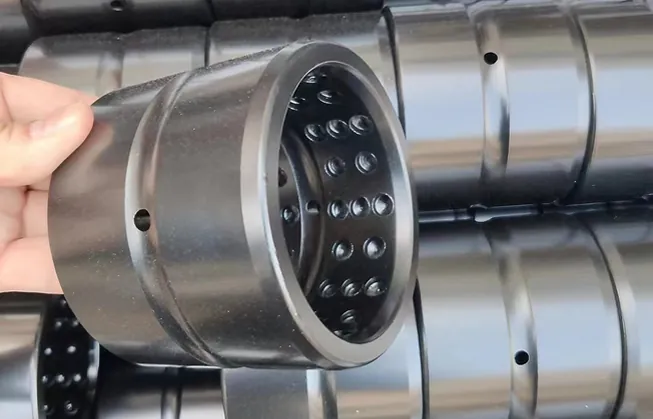

Wear-Resistant Alloy Bushing

-

Material:40cr/45#/20CrMnTi

Technique:Forging & casting

Heat treatment:50-53 HRC

Warranty time:2000 hour (Normal life 4000hours )

Certification:ISO9001-9002

Color:Customized

MOQ:20 pieces

Delivery Time:Within 25 days after contract established

Description

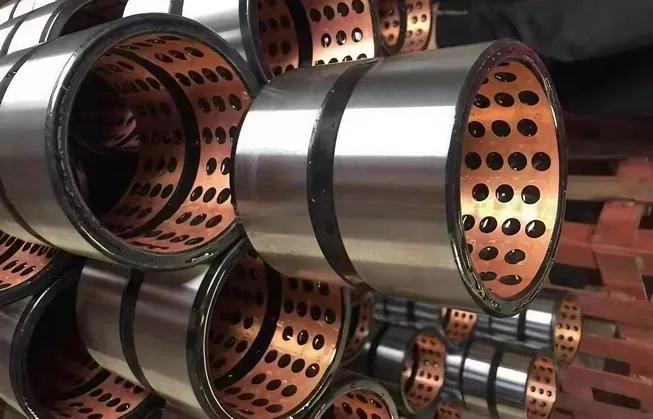

The bucket pins and Bushing is wear part for excavator bucket attachments.

There are some different materials for bucket bushings. 45# carbon steel, 40Cr and 20CrMnTi are mainly three materials for them.

Besides raw materials, heat treatment is also very important for its quality.

We offer premium quality Bucket Pin & Bucket Bushing for renowned brands like CAT, CATERPILLAR, DAEWOO, DOOSAN,

HITACHI,JCB,JOHN DEERE,KATO,KOMATSU,KUBOTA,LIEBHERR,MITSUBISHI,CASE,SHANTUI,TEREX,VOLVO,YANMAR,and many more.

Rest assured, our products boast an extended lifespan, ensuring reliable performance even under the harshest conditions.

Image Gallery

Models

| PART NO. | BUCKET BUSH | Model | Material |

| 90x105x100 | BUCKET BUSH | PC350 | 40Cr |

| 100x115x100 | BUCKET BUSH | PC450 | 40Cr |

| 100x115x110 | BUCKET BUSH | PC450 | 40Cr |

| 100x115x120 | BUCKET BUSH | PC450 | 40Cr |

| 100x120x110 | BUCKET BUSH | PC450 | 40Cr |

| 100x120x95 | BUCKET BUSH | PC450 | 40Cr |

| 90×106×90 | BUCKET BUSH | CAT 325DL | 40Cr |

| 90×105×90 | BUCKET BUSH | CAT 325DL | 40Cr |

| 80×95×90 | BUCKET BUSH | CAT320DL | 40Cr |

| 80×96×90 | BUCKET BUSH | CAT320DL | 40Cr |

| 70×86×70 | BUCKET BUSH | Doosan DX225-LCA | 40Cr |

| 70×85×70 | BUCKET BUSH | Doosan DX225-LCA | 40Cr |

| 90×105×100 | BUCKET BUSH | Hyundai 290-7 | 40Cr |

| 90×105×100 | BUCKET BUSH | Doosan DX300-LCA | 40Cr |

| 80x95x80 | BUCKET BUSH | PC200 | 40Cr |

| 70x85x80 | BUCKET BUSH | PC200 | 40Cr |

FAQs

1. What are some common maintenance practices for Track Pins and Bushings?

Regular inspection and lubrication are essential maintenance practices for track pins and bushings. Inspecting for wear and tear, replacing worn components, and keeping the assembly properly lubricated help extend the lifespan and ensure optimal performance of the machinery.

2. How can operators identify issues with Track Pins and Bushings?

Operators should regularly check for signs of wear, such as increased play or looseness in the track assembly, unusual noises during operation, or visible damage to the pins and bushings. Any abnormalities should be promptly addressed to prevent further damage.

3. Can Track Pins and Bushings be replaced individually, or are they typically replaced as part of a larger assembly?

Track pins and bushings can be replaced individually if only certain components are worn or damaged. However, in cases where significant wear or damage is

observed across the entire assembly, it may be more practical to replace the entire track assembly for better overall performance and longevity.

Literature

Comment

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

When seeking manufacturers and suppliers for Wear-Resistant Alloy Bushing, choosing SAIVS is your wise decision.

We pride ourselves on high quality, diverse options, competitive pricing, and swift delivery.

Engage with our experts now to explore further insights into our Wear-Resistant Alloy Bushing product solutions.